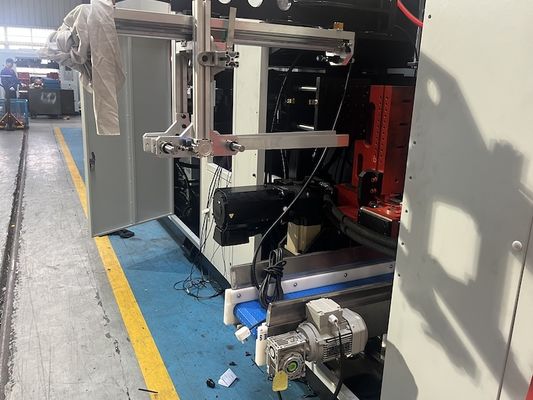

HDPE LDPE PP MP75FD automatische Blasformmaschine

Beschreibung des Produkts

Die automatische Schlagformmaschine ist eine industrielle Ausrüstung zur Herstellung hohler Kunststoffgegenstände, die bei der Herstellung von Flaschen, Behältern, Gläsern und Tanks eine entscheidende Rolle spielt.Das Verfahren besteht darin, das Kunststoffmaterial zu erhitzen, bis es biegsam ist, dann mit Druckluft, um sie in die Form der Form auszudehnen, um einheitliche und präzise Endprodukte zu gewährleisten.Automatisierung verbessert die Produktionseffizienz und hält hohe Qualitätsstandards bei der Herstellung hohler Kunststoffwaren.

Wesentliche Merkmale

Voll automatischer Betrieb:Reduziert die Arbeitskosten durch automatisches Vorformladen, Erwärmen, Blasen und Auswerfen von Flaschen.

Hohe Produktionskapazität:Bei den Optionen mit mehreren Hohlräumen (2-12+ Hohlräume) werden für die mittlere bis große Produktion 1.000 bis 20.000 Flaschen/Stunde produziert.

Konsistente Qualität:Eine präzise Steuerung der Heiztemperatur, des Dehnungsverhältnisses und des Blasdrucks sorgt für eine gleichmäßige Wandstärke und eine hohe Klarheit.

Energieeffizient:Infrarot-Heizung und servo-getriebene Komponenten reduzieren den Stromverbrauch mit Zonenheizungstechnologie.

Versatile Formgebung:Das schnelle Formenwechselsystem unterstützt verschiedene Flaschenarten (Getränke, Öl, Kosmetik, Pharma).

Benutzerfreundlich:PLC-Touchscreen-Schnittstelle mit Fehlerdiagnose und automatischen Alarmen für einfache Bedienung und Wartung.

Weite AnwendungsbereicheProduziert PET-, HDPE- und PP-Flaschen für verschiedene Branchen, einschließlich Getränke, Chemikalien und Pharmazeutika.

24/7 Betrieb:Konzipiert für die kontinuierliche Produktion, integriert sich nahtlos mit Füll-, Etikettierungs- und Verpackungslinien.

Technische Spezifikation

| Parameter |

MP75FD φ80 |

| Material |

PE PP |

| Maximale Behälterkapazität (L) |

0.1 |

| Anzahl der Matrize (Set) |

4 |

| Maschinenabmessungen (L × W × H) (M) |

3.6 mal 2,2 mal 2.36 |

| Gesamtgewicht (Tonne) |

5.5 |

| Klemmkraft (KN) |

120 |

| Plattenöffnungsstränge (mm) |

180 bis 480 |

| Schaltstrich (mm) |

300 |

| Maximale Formgröße (W × H) (mm) |

460 × 450 |

| Schraubendurchmesser (mm) |

80 |

| Schraub L/D-Verhältnis (L/D) |

24 |

| (HDPE) Plastifizierungskapazität (kg/h) |

100 |

| Schraubwärmezone (Zone) |

4 |

| Schraubheizleistung (kw) |

15.85 |

| Leistung der Lüfter (kw) |

0.28 |

| Ausrüstungskraft (kW) |

30 |

| Die Heizungszone (Zone) für den Druckkopf |

3 |

| Leistung der Druckluftheizung (kw) |

8 |

| Leistung des Elektromotors (kw) |

11 |

| Luftdruck (Mpa) |

0.6 bis 0.8 |

| Gesamtleistung der Maschine (kw) |

65.13 |

| Durchschnittlicher Energieverbrauch (kw) |

31 |

| Verbrauch von Druckluft (m3/min) |

1.2 |

| Kühlwasserverbrauch (L/min) |

40 |

Anwendungen

Verpackung von Getränken:Mineralwasser, Saft, kohlensäurehaltige Getränke und Teeflaschen.

Lebensmittelverpackung:Speiseöle, Milchprodukte und Gewürzbehälter.

Haushalt und persönliche Pflege:Waschmittel, Shampoos, Duschgel und Kosmetika.

Arzneimittel:Medizinflaschen und Nahrungsergänzungsmittelbehälter.

Chemie und Industrie:Schmieröl, Pestizide und große Plastikfässer.

Zu Hause und täglich:Plastikspielzeug, Krüge und Lagerbehälter.

Medizinisches und Gesundheitswesen:Desinfektionsmittel und medizinische Sprays.

Verpackung nach Maßgabe:Prototypen und Kosmetikflaschen.

Anpassungsmöglichkeiten

MEPER bietet kundenspezifische MP75FD Automatic Blow Moulding Machines mit CE- und ISO9001:2008-Zertifizierung.und In-Mold-Labeling (IML) -TechnologieDie Standard-Exportverpackung gewährleistet eine sichere Lieferung innerhalb von 25-35 Werktagen mit flexiblen Zahlungsbedingungen (L/C, T/T) und einer Lieferkapazität von 100 Stück/Monat.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!